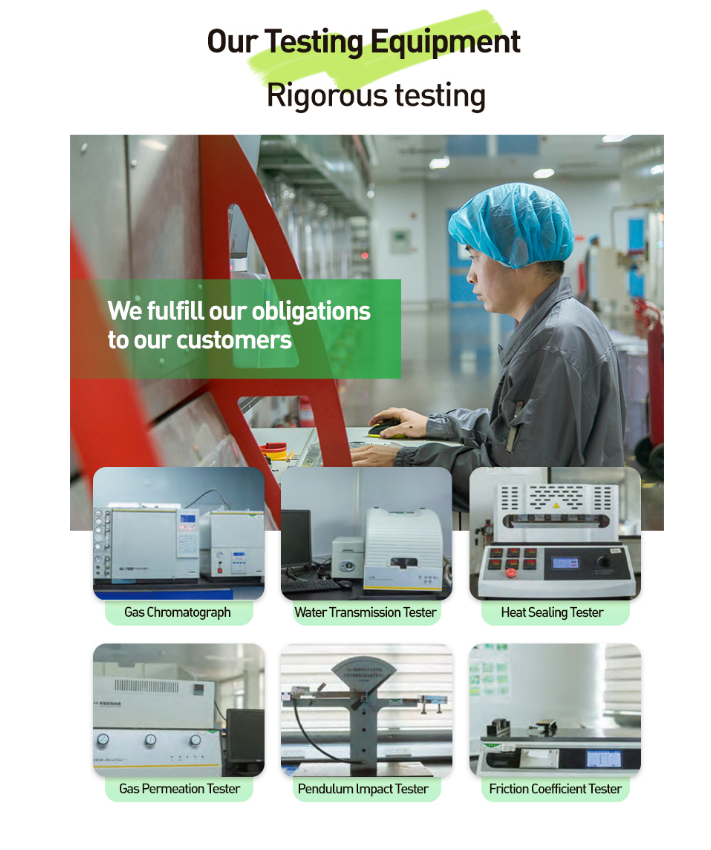

Testing Equipment

At Shangdong Packaging, we understand that the integrity of your product begins with flawless packaging. That’s why every bag we produce undergoes rigorous testing at every stage—pre-production, in-process, and post-production—to guarantee zero defects, airtight seals, and unmatched durability.

Our Commitment to Quality

Pre-Production Testing

Raw materials are analyzed using Gas Chromatographs to detect impurities or contaminants, ensuring only premium-grade polymers enter production.

Water Vapor Transmission Testers evaluate moisture resistance, critical for products sensitive to humidity.

.

In-Process Quality Control

Heat Seal Testers monitor seal strength in real-time, preventing weak bonds or leaks.

Coefficient of Friction Testers ensure smooth handling and safe transportation by optimizing surface properties.

.

Post-Production Verification

Gas Permeability Analyzers validate barrier performance against oxygen, CO₂, and other gases.

Pendulum Impact Testers simulate real-world stress to confirm tear resistance.

Cutting-Edge Technology

State-of-the-art instruments like Gas Chromatographs and Pendulumresters deliver data-driven precision.

End-to-End Assurance

No bag leaves our facility without passing 100% inspection.

Industry Expertise

Tailored solutions for food, pharmaceuticals, electronics, and more.